Corporate Information

Message from Managing Director

Carrying on the spirit of

“Honesty and Progressive”

from the company’s founding in 1889, we create a new future for manufacturing.

President and Representative Director,

Akira NAKANISHI

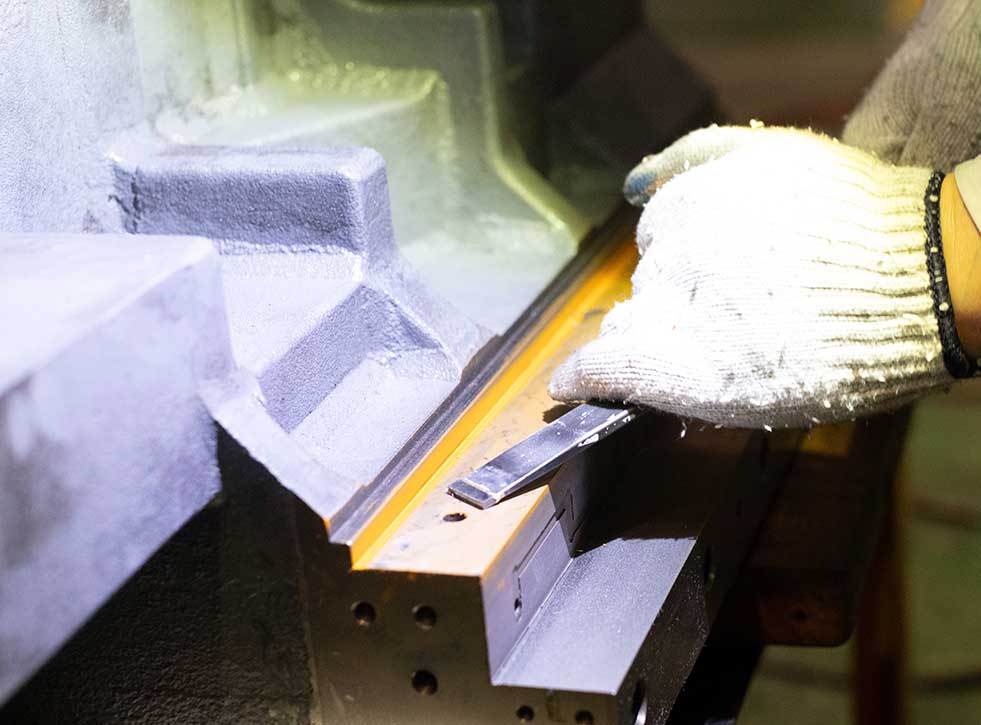

『Machine tools, diesel engines and screw extruders. Japan’s firsts all these came from Ikegai』

Ikegai was founded in 1889 and was the first manufacturer manufacturing machine tools (lathes) in Japan. At that time, Japan imported machine tools from Europe, but it was essential to produce them domestically to support and grow Japanese manufacturing. With this background, our founder Shotaro Ikegai completed the first domestically produced lathes, two English-style 9-foot lathes, in 1889. These lathes are not only the first domestically produced lathes (donated and exhibited at the National Museum of Nature and Science), but also the oldest existing ones in Japan. This is the origin of Ikegai’s spirit of “Honesty and Progressive”. The spirit is accepting what is necessary for the development of society with honesty and creating new things with an progressive spirit.

Ikegai’s domestic firsts in this spirit were not limited to machine tools; Ikegai developed Japan’s first marine diesel engine in 1926. And in 1930, NIPPON MARU equipped with Ikegai’s first large marine diesel engine, was put into service. The NIPPON MARU holds the world’s record for the longest operating period of 54 years, and the engine is still on display at the Sail Training Ship NIPPON MARU Yokohama Port Museum. Currently, we are the sole Japanesed agent for MAN who is the largest diesel engine manufacturer in Germany and we take care of all overhaul and other maintenance work in Japan.

Furthermore, we created Japan’s first screw-type extruder in 1951. Our screw-type extruders have contributed to the evolution of plastic materials. We have continued to pursue and develop know-how on screw shapes and mixing conditions for various resin combinations in cooperation with various customers, and continue to play an active role in diverse industries such as chemicals, automobiles, and food industries. In recent years, we have developed a full lineup of single-axis and twin-screw extruders that can handle not only conventional plastic materials but also biodegradable resins.

『With the responsibility and mission to pass on and evolve our more than 130 years of technology』

The common factor among lathes and other machine tools, diesel engines, and extruders is that they have been used by our customers for more than several decades, and we continue to maintain and improve them while producing products that meet new needs. We believe that we are able to do this because the technologies and skills we have accumulated from the past have been passed down to the next generation in both written and nonwritten form, and because we have continued to train our employees. This is why we have been able to continue the same business for more than 130 years. We believe that it is our responsibility and mission to continue to pass on the technology and skills that have been handed down to the next 10, 30, and 100 years. The speed of change in the environment surrounding us is accelerating, and the machines demanded by our customers are also changing. While responding to such changes, we will continue to maintain and improve the machines we delivered more than 30 years ago. We will continue to embody the spirit of “Honesty and Progressive” in our business.

Corporate Profile

| Name | Ikegai Corp |

|---|---|

| Founded | May, 1889 |

| Incorporated | July, 1949 |

| Capital | 90 million yen |

| Settlement period | December 31 |

| Executive | Representative Director and CEO Shunka CHO President and Representative Director and COO Akira NAKANISHI |

| Employees | (Non-consolidated) 200 (January, 2024) (consolidated)1000(January, 2024) |

| Description of business | Manufacturing, repair, sales, and installation of machine tools, etc. |

| Main Business Activities | Machine tool: CNC lathe, machining center, and CNC boring milling machine Industrial machinery: Extruder, seat and film molding machine Engine: Marine engine |

| Affiliates | Ikegai Diesel Corp Ikegai (Shanghai) Machinery Company Ikegai Metal Corp SHIN NIPPON KOKI CO.,LTD |

| Area of business operation | Tsukuba factory (where the headquarters is located) Lot area 113,903㎡(34,516 tsubo) Floor space of building 30,009㎡(9,094 tsubo) Main plant, Large-scale product plant, Plastic center No.1 plant, No2 plant |

| ISO9001 certification acquired | June 2012 |

Company history

| 1889(M22) | Shotaro Ikegai established the Ikegai Plant in Shibakanasugikawaguchicho, Tokyo. Completed Japan’s first lathe production. |

|---|---|

| 1896(M29) | Manufactured Japan’s first oil engine. |

| 1905(M38) | Started mass production of the Ikegai-model standard lathe that was groundbreaking at that time. |

| 1906(M39) | Established Ikegai Ironwork Limited Partnership. |

| 1913(T2) | Incorporated as Ikegai Ironworks Corp. |

| 1915(T4) | Advanced to the world market with machinery made in Japan by exporting 5 sets of eight-foot lathe. |

| 1916(T5) | Exported 585 sets of 30ps gasoline engines with an order from the Russian government in 6 months. |

| 1920(T9) | Manufactured Japan’s first air injection diesel engine. |

| 1926(T15) | Produced Japan’s first high-speed newspaper printing machine. Completed the production of Japan’s first solid injection diesel engine. |

| 1927(S2) | Started the production of automatic type casting machinery and eliminated the need to import these products into Japan. |

| 1934(S9) | Developed a fast newspaper printing machine that can print 180,000 copies. |

| 1937(S12) | Completed Japan’s first high-speed highly effective twin headed milling machine and delivered it to the Ministry of Railroad. |

| 1941~1944 (S16~19) |

During World War II under All-mobilized R&D orders, developed the latest models of single-axis and four-axis auto lathes, strong auto lathe for shell manufacturing, airplane engines, cylinder liners FB model fine boring machine, specialized machinery for military aircraft engines, “Homare”, and fine boring milling machine. |

| 1949(S24) | Established “Ikegai Ironworks Corp” under Enterprise Reorganization Act. |

| 1950(S5) | Produced plastic extruder, PVC wire coating machine. Completed Japan’s first multi-color high-speed newspaper printing machine and delivered it to Asahi Shimbun and others |

| 1951(S26) | Developed Japan’s first copying lathe and stimulated Japanese industrial machinery industry that was in the recession mode after the war Successively introduced auto copying lathe and copying roll lathe. |

| 1953(S28) | Produced Japan’s first spark electrical discharge machine “JAPAX” |

| 1957(S32) | Delivered 850ps dynamos to Tokyo Tower. |

| 1958(S33) | Entered technical alliance with R.H. Windsor , a British plastic machine maker and produced series of excellent machines. |

| 1960(S35) | Sealed technical alliance with Daimler-Benz for high-speed diesel engine. |

| 1965(S40) | Received “The Japan Society of Mechanical Engineers Award” for the A20 lathe which is a unique product with many new functions. |

| 1966(S41) | Introduced three numerically-controlled industrial machinery including machining center at the 3rd Japan Industrial Machine Exhibition. |

| 1968(S43) | Completed Japan’s first computer-controlled industry machine integrated management system and delivered to Japan National Railroad. |

| 1969(S44) | Received “the Minister of state for Science and Technology Award” and “The Japan Society of Mechanical Engineers Award” for controlled industry machine integrated management system. |

| 1974(S49) | Awarded “The Okochi Memorial Prize” for screw die method sheet production technology. Received “Automation Machine Development Award” for turning center FT500NA. Obtained the 4th Machine Design Award “Japan Industrial Machine Award” for GT110 double-axis extruder. |

| 1975(S50) | Developed non-circular machining lathe. Awarded “10 top new products of 1975” |

| 1976(S51) | Produced super-large roll lathe TRL125 that has the world strongest cutting power. |

| 1977(S52) | Automated small-sized NC lathe FX20N with some limitation by attaching autoloader device. |

| 1978(S53) | Sealed OEM sales contract for small-sized engine with MAN, Germany. Completed strong super-large machining center ANC180FM. |

| 1985(S60) | Newly constructed Tsukuba Plant in Namekata city (former Namekata county), Ibaraki to meet the expansion of business. |

| 1987(S62) | Completed Japanese top-class turning center, TNC56. Developed CPU system EX-100 that realizes FA plastic machinery. |

| 1988(S53) | Received Japan’s Society for the Promotion of Machine Industry “Automated Machine Development Award” for vertical boring and turning mill machining center “Hitotsubokun” |

| 1990(H2) | Developed the TM25YS. This is a 8 axis control machining turn that makes 6 face processing possible. |

| 1991(H3) | Changed company name from “Ikegai Ironworks Corp” to “Ikegai Corp” |

| 1993(H5) | Developed the CNC boring milling machine NB110T. |

| 1995(H7) | Developed the 1500CPL, CNC crankpin lathe for large crank for vessel. |

| 1998(H10) | Developed the U-axis horizontal machining center, TH500 and TH600. |

| 1999(H11) | Established a centralized processing plant in Kawaguchi Plant. |

| 2001(H13) | Filed for court protection at the Tokyo District Court. Capital 100% reduced. New capital 10 million yen. |

| 2002(H14) | Closed down Kawasaki and Kawaguchi Plant. Integrated into Tsukuba Plant. Received orders for honing center and delivered the orders. |

| 2004(H16) | Ended civil rehabilitation proceedings (a half year earlier than a plan) Manufactured and delivered a large-scale diesel engine part processing special machine. Shanghai Electric Group Co., Ltd made a capital participation. New capital 490 million yen. |

| 2005(H17) | Established Ikegai Diesel Corp. Completed a large-scale assembly and machine processing plant that facilitates 50 ton and 30 ton crane to meet increasing orders for large-scale machine tools. Opened Shanghai Office in Shanghai, China. Established Ikegai (Shanghai) Machinery Company in Shanghai, China. |

| 2006(H18) | Began the production and sales of small-and mid-sized machine tools at Ikegai (Shanghai) Machinery Company. |

| 2009(H21) | Facilitated 4 large-scale processing machines at Ikegai (Shanghai) Machinery Company. |

| 2012(H24) | Developed “HM3, HM4, and HM5”, a fusion of machining center and honing machine |

| 2014(H26) | Capital participation by Fair Friend Group |

| 2016(H28) | SHIN NIPPON KOKI CO., LTD. joined as a group company |