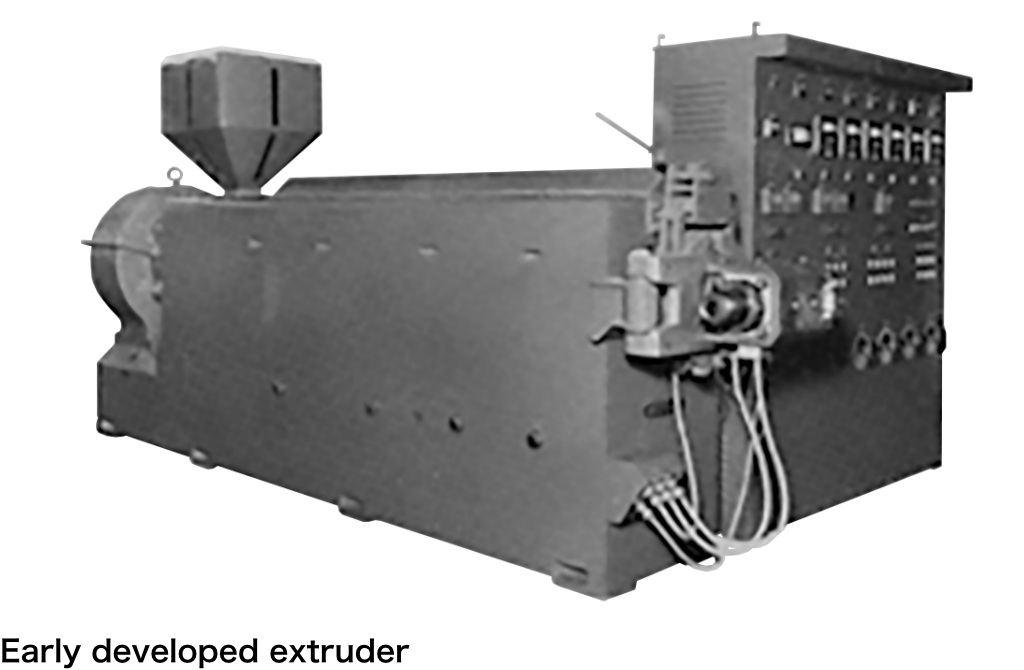

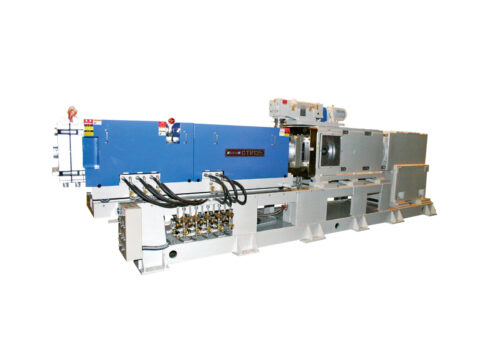

Industrial machine

It has been about 70 years since we produced the first screw-type extruder in Japan in 1951. Our Industrial Machine Division has developed a wide product lineup from single screw extruders to twin screw extruders in order to meet various customer needs.

We will continue to provide new values to our customers with our experience and technical capabilities.

Single screw extruder

We propose the most suitable model for each customer’s request, from the variety of machine model to the design of screw shapes based on our extensive experience and knowledge.

FS

Standard model extruder for 40 years

GS

Extruder capable of high load extrusion which is difficult forming

SX

Extruder capable of low temperature and high discharge of olefin resins

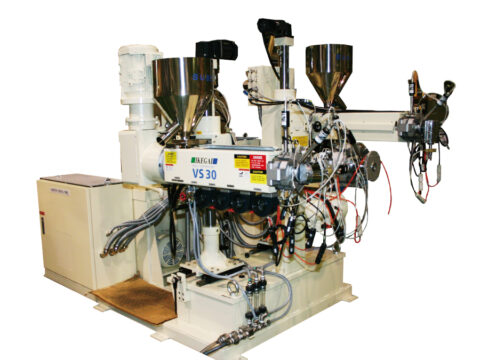

VS

Extruder that can be used as an auxiliary extruder for two-color extrusion or as a stand-alone molding

COMBI

Combined extruder of FS and VS extruders in the same frame

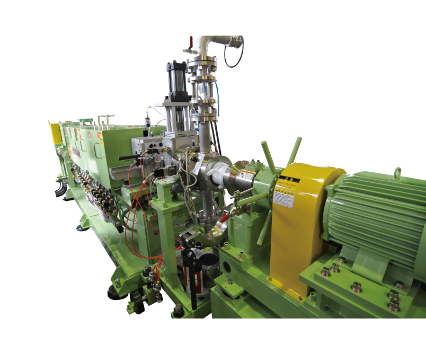

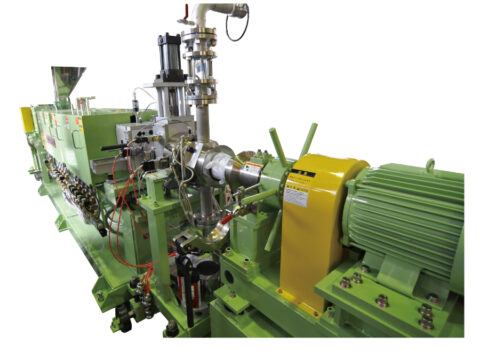

Twin screw extruder

Since the first twin-screw extruder was domestically produced in Japan in the 1950s, we have been offering a lineup of various types of twin-screw extruders, from low-speed extruders dedicated to PVC to high-torque, high-speed extruders for super engineering plastics.

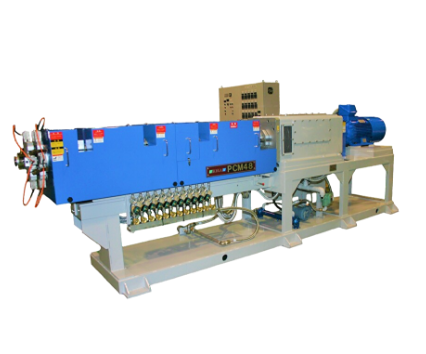

PCM・PCM-HTS

Fully engaged, high-speed twin screw extruder with wide range of controllable kneading capabilities and high energy efficiency.

SKPCM

Extruder that enables stable molding of recycled and biodegradable resins

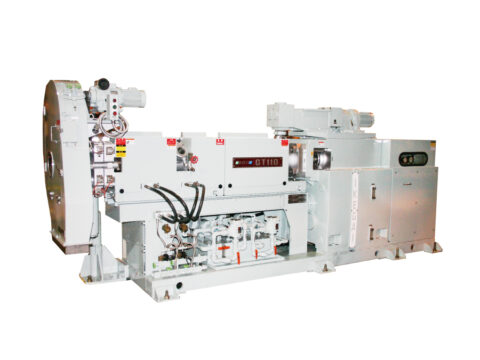

GT

Proven twin screw extrusion with co-directional rotation

GTR

Dedicated PVC and power-saving extruder with different direction rotation

GTC

Extruder with different direction rotation good for molding rigid PVC and compounds production.

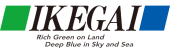

Production equipment

We manufacture and sell equipment for producing pellets, film/sheets, and pipes/tubes optimized for the characteristics of resins. We can also customize the equipment to the specifications best suited for the molding application, including system design that directly affects the usability of the equipment.

Pelletizing Equipment

Any resin, any additive, into high quality pellets

Sheet / Film manufacturing equipment

Sheet/Film manufacturing equipment

featuring Ikegai's T-die series

Pipe / Tube extrusion equipment

From large-diameter polyethylene pipes to medical tube molding

Deformed molding equipment

From deformed molding to deformed coating

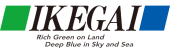

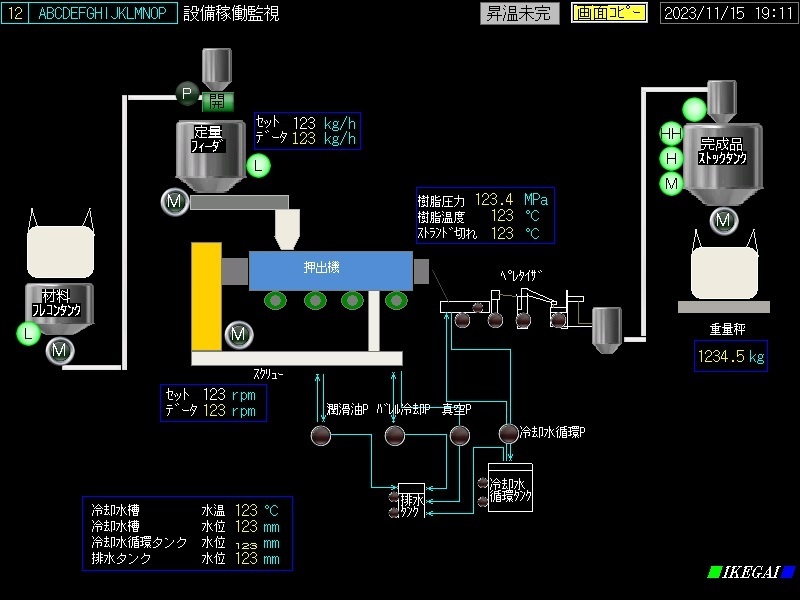

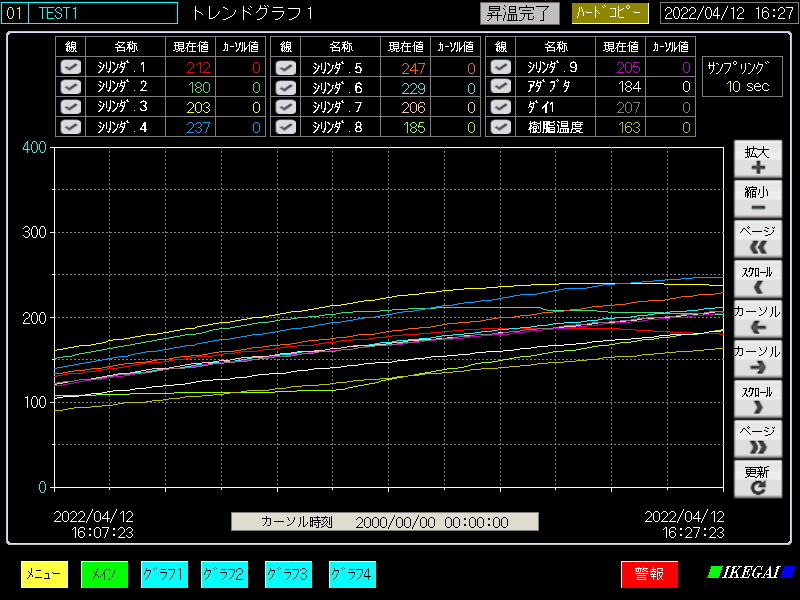

Digital solution

Ikegai’s control system EX100S can control the extruder and molding machine at once, and various functions can be added by using EX100S system.

Easy, convenient

- Batch display of actual measured values such as temperature and speed

- Input control settings via touch panel

- Recalls resin manufacturing conditions and various setting values stored for each product type

Wide, entire view

- Visual display of line operating status and alarms

- Automatic step-starting of each process equipment and extruder

Detail, accurate

- Log each process data

- Display in lists and graphs

- Log and alarm data file output

- Alarm histories

Cooperation

- Control data I/F with host, DCS, instrumentation PLC, etc.

- Remote maintenance from customer’s office or Ikegai

New material development

Plastic Center

We can verify the screw shape and operating conditions that greatly affect resin properties and molding. We can make resin + additive blends, pellet prototypes, sheet/film, and tube/pipe prototypes according to your needs. Please utilize our center to select the most suitable extruder.

Equipment

- Single screw extruders: Φ30-90mm, 6 units

- Twin screw extruder: Φ30-80mm, 7 units

- Tandem extruder: 1 unit

- Various types of granulation equipment

- Sheet and film forming equipment

- Pipe and tube forming equipment

- Other auxiliary equipment

Applicable Resins

- General-purpose plastics

- Super engineering plastics

- Biodegradable resins

- Naturally derived materials

(wood, bamboo powder) - Others

(We can formulate according to your requests.)

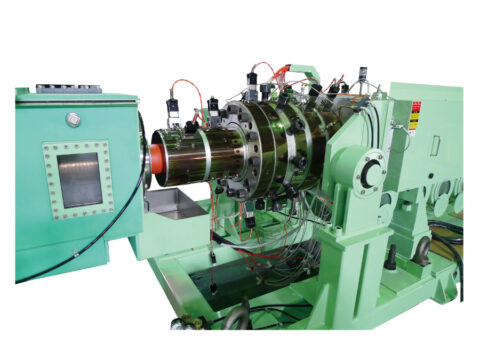

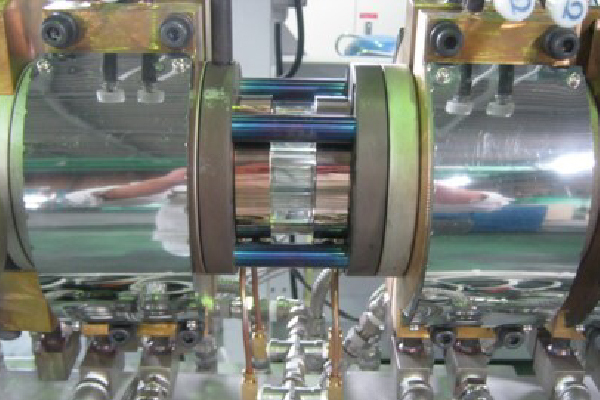

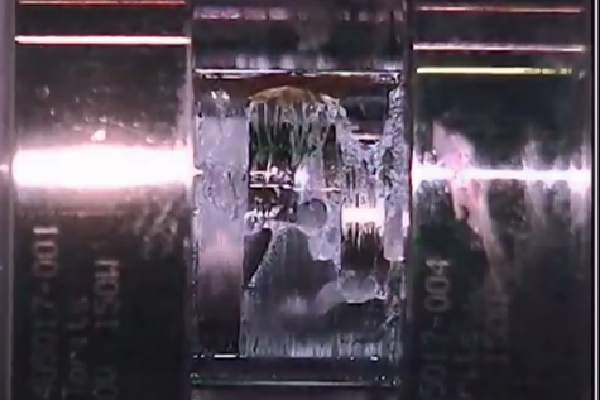

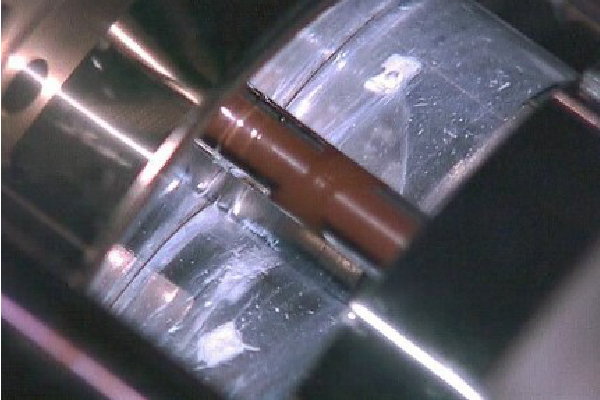

Visualized Barrel for Basic Research

The visualized barrel is a barrel with a transparent part on the cylinder of PCM30 twin-screw extruder, which is widely used for research and testing, to observe the state of kneading and dispersion inside the cylinder.

【Features】

- Maximum operating temperature 300°C

- Can see engaging parts

- Temperature rise and cooling can be freely changed

- Can be incorporated into existing machines

Visualized Barrel video

Visualization of the molten conditions can be used to verify the effects of screw elements and for basic research.

Head Office / Tsukuba Factory

920-52, Serizawa, Namegata

Ibaraki 311-3501 Japan

TEL: +81-299-55-3111

FAX: +81-299-55-3119

Plastic Center

920-73, Serizawa, Namegata

Ibaraki 311-3501 Japan

TEL: +81-299-55-3641

FAX: +81-299-55-3654

Service / Support

We have established service centers at each of our locations to ensure that our existing and new customers can use our machines for a long time with no worries. We provide full support from prompt maintenance for breakdowns and repairs to mid- to long-term after-sales support for relocation, retrofitting, overhauls, etc.

Equipment Launch Support

At our assembly plant, which has a large site, we can perform test runs and make adjustments on the same line configuration prior to shipment.By making adjustments in advance, the process from equipment installation to the start of production can proceed smoothly.

After Service

Technicians in charge of service are stationed at the factory and each sales office. We have a system in place to handle everything from routine maintenance to unexpected problems.Even aging equipment can be fully overhauled and made to look like new again.

Gear Box Overhaul

This section introduces the process from request to completion of overhaul.

- Discovery of problems during periodic inspections by our service staff and inquiries from customers when abnormal noises or heat generation occur.

- Discussion of gearbox overhaul and quotation

*After disassembly, there is a possibility of additional parts that need to be replaced. - Discussion of installation schedule and delivery date after order is placed

- Gear box removal work at customer’s site

- Gear box overhaul at our Tsukuba factory

- Inspection of overhauled products

- Gear box assembly at customer’s site

Completion of overhaul

Inquiries

For inquiries regarding breakdowns, repairs, and various types of maintenance, please call, fax, or e-mail our nearest sales office.

Tokyo Office

3-43, Egasaki-cho, Tsurumi-ku, Yokohama

Kanagawa, 230-0002 Japan

TEL: +81-45-580-3651

FAX: +81-45-573-2851

Nagoya Office

Hirokojisakae Building 8F

2-4-1, Sakae, Naka-ku, Nagoya

Aichi, 460-0008 Japan

TEL: +81-52-211-7912

FAX: +81-52-211-7913

Osaka Office

2-500-1, Takao, Miami-ku, Sakai

Osaka, 590-0157 Japan

TEL: +81-72-355-1810

FAX: +81-72-355-1812