Machine Tool

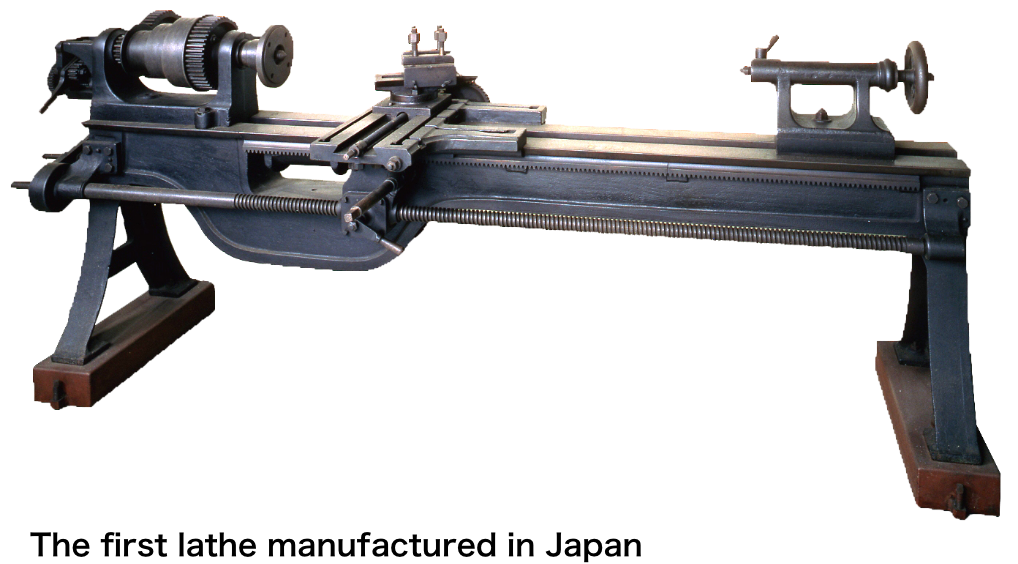

Since our founding in 1889 when we manufactured the first domestic lathe, we have consistently mastered machine tool, the mother of all machines, and have developed diesel engines, printing machines, plastic processing machines, and other products.We will contribute to the development of society by further enhancing our unique tailor-made technology cultivated over 130 years and creating new value, thereby pioneering the future of machine tool.

- Honesty Manufacturing~Features of Ikegai lathe〜

- Progressive Manufacturing~U-axis Machine〜

- Service / Support

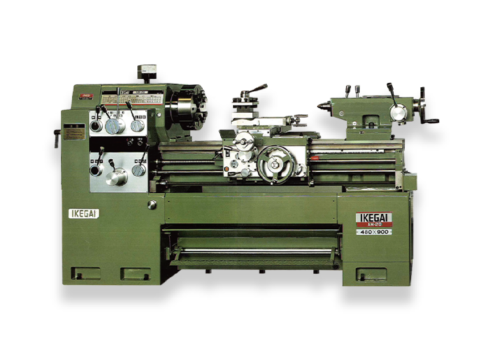

Lathe・Composite Lathe

We offer lathes from long-established Ikegai. We are backed up with achievements withing several industries such as seacraft and iron manufacturing that use large type lathes.

Conventional lathe

NC lathe

VT

Single column CNC vertical lathe capable of face milling, boring and outer diameter turning

- Max turning diameter(mm)

- φ1,350

- Max load capacity (kg)

- 4,000

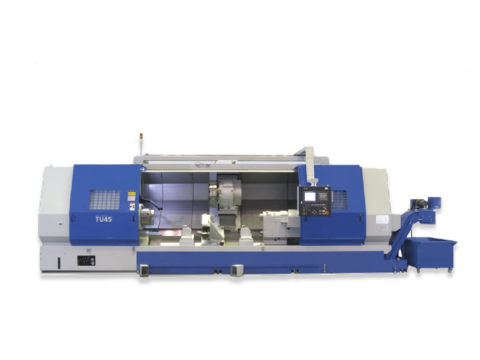

TU

Great capability for heavy-duty cutting of large-diameter center workpieces and chuck workpieces

- Max swing (mm)

- φ500 ~ φ850

- Max turning diameter (mm)

- φ350 ~ φ650

TC

CNC lathe designed to process as large a workpiece as possible

- Max swing (mm)

- φ500

- Max turning diameter (mm)

- φ370

AU(ANC)

Horizontal two-guideway CNC lathe with great accessibility to the workpiece center.

- Max distance between centers (mm)

- 1,000~

- Spindle speed(min-1)

- 1.6~500

TNC

Large three-guideway CNC lathe with compact footprint.

- Max distance between centers (mm)

- 1,000~

- Spindle speed(min-1)

- 1.6~400

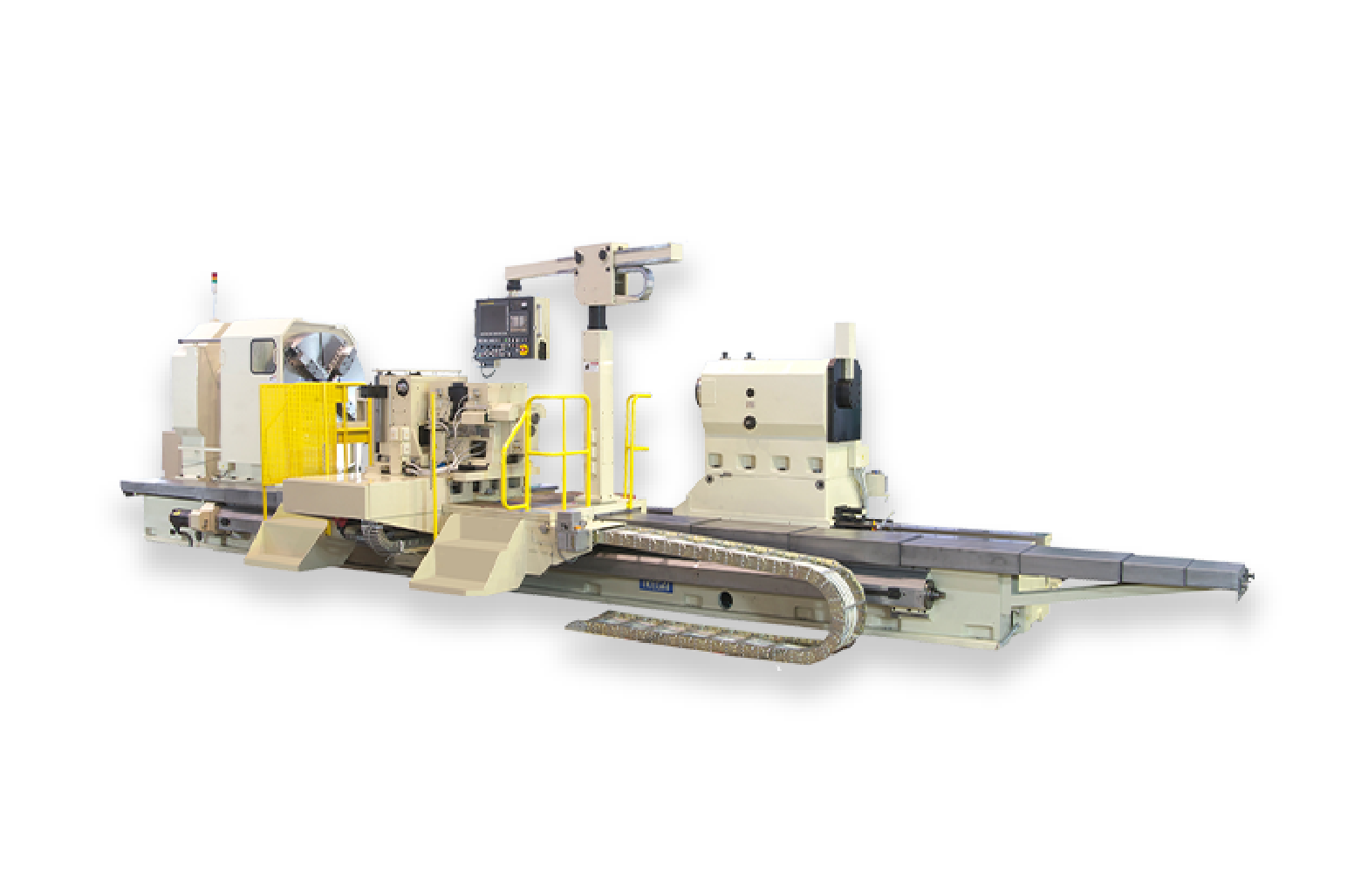

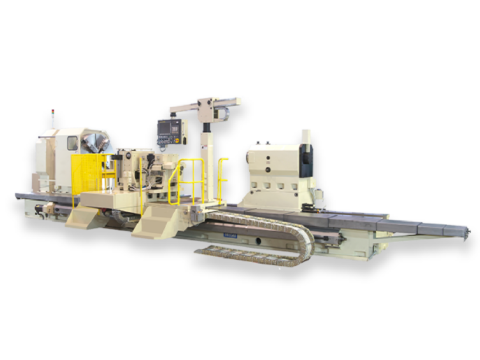

RNC/TNC-S

Horizontal four-guideway CNC lathe with separated / integrated saddle and work bed

- Max distance between centers (mm)

- 6,000~

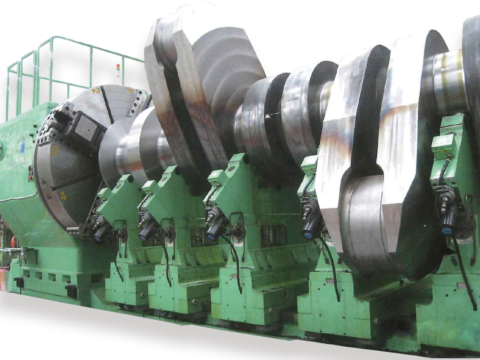

Special Purpose Machine

By using our know-how on large type machining centers, we offer new and specialized machines that accommodate the needs of our customers. We are backed up by achievements in the aerospace and construction machinery industries.

Special machine for rail industry

Special machine for material

Special machine for shipbuilding

Honing Center・U-Center

A multi tasking honing machining center made up of a combination of high-efficiency boring machining and high-precision honing finishnig.

Machining centers, either vertical or horizontal, equipped with U-axis mechanism are U-centers.

Honing center

U center

Horizontal Boring Machine

A horizontal boring machine equipped with U-axis mechanism.

Horizontal boring machine

BNC

U-axis control equipped CNC horizontal boring machine that can apply the built-in face plate

- Table size (mm)

- 950 x 1,050 / 1,400 x 1,600

- Spindle speed (min-1)

- 10 ~ 1,600

NB

CNC horizontal boring and milling machine with excellent operability

- Table size (mm)

- 950 x 1,050 ~ 1,600 x 1,800

- Max load capacity (Kg)

- 2,500 ~ 10,000

Honesty Manufacturing ~ Features of Ikegai lathe ~

Ikegai Lathe, which mainly manufactures medium and large lathes, has been highly evaluated by customers as a highly rigid lathe, and this feature is incorporated throughout the lathe series.

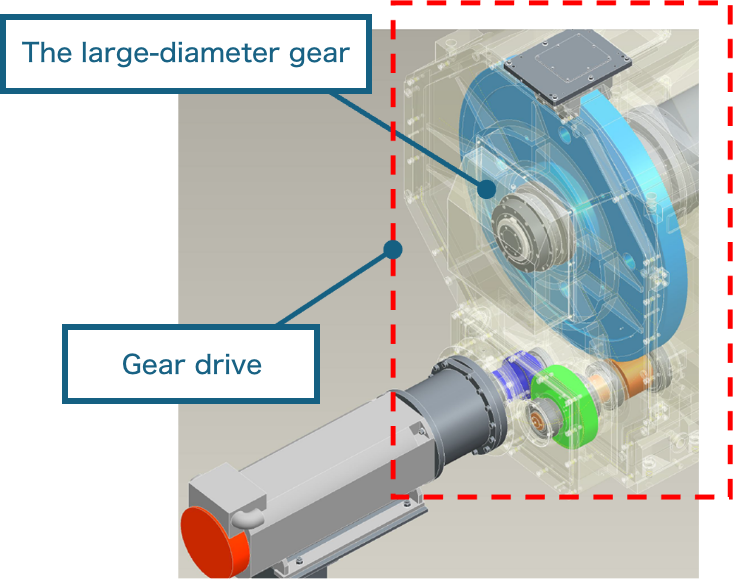

■High-rigid spindle structure

- Spindle drive provided gear drive to achieve a high natural frequency and ensure strong vibration resistance.

- The large-diameter main gear is located at the rear of the spindle head to provide high rotational torque and maintain high rigidity.

■Stable & High-precision bed / Sliding surface

- A wide bed is adopted so that the cutting force is always received by the bed. The wide bed ensures stable cutting.

- To maximize the effect of the wide bed, the sliding / joint surfaces are fully finished by hand scraping to minimize gaps.

Kisage (Hand scraping), the principle of Ikegai’s manufacturing

- Sliding surfaces are finished with hand scraping to achieve high accuracy/stability. Flatness accuracy is 0 to 2μm.

- It takes 3 months to learn the basics of hand scraping and will not be allowed to execute work until you have mastered the basics.

■Tailstock to support stable power

- Disc springs are incorporated in the quill moving mechanism, and the deflection of the disc springs are used as thrust.

- Since the quill follows the expansion and contraction of the workpiece length due to processing heat, etc., there is no significant change in the thrust force.

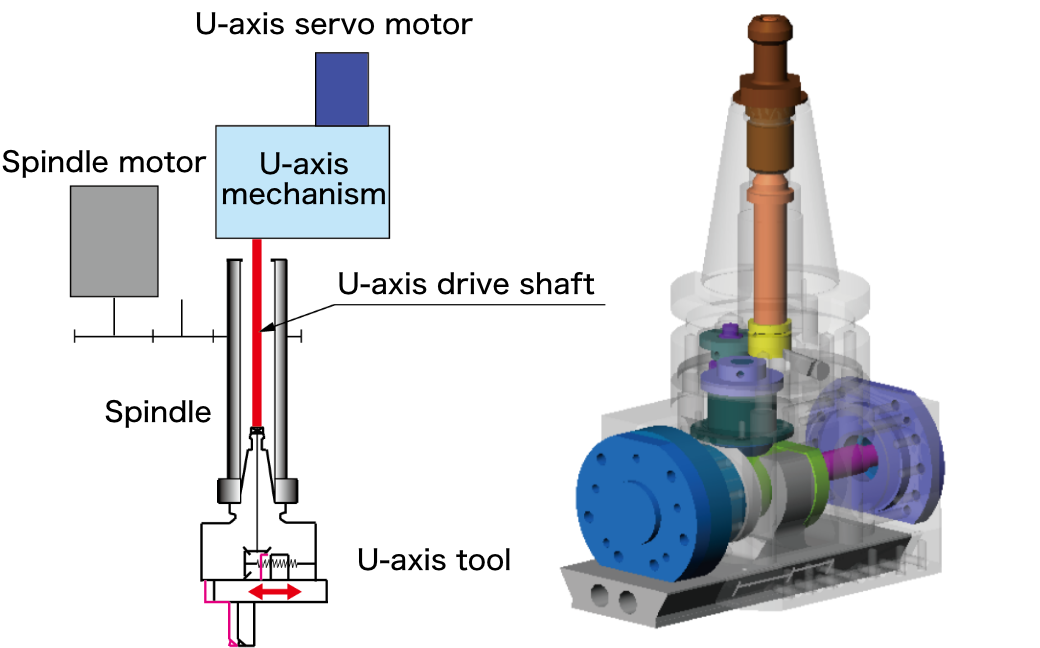

Progressive Manufacturing ~ U-axis Machine ~

Ikegai proposes special and dedicated machines to meet customers’ needs to the maximum extent by making full use of its sincere craftsmanship, experience and know-how accumulated over the years.

Ikegai has produced many machines using U-axis mechanism. Honing process also uses this U-axis mechanism.

■U-axis Machining & its advantages

Turning enabled by NC control (U-axis) of the tool edge in the radial direction on a machining center. This allows a reduction in the number of tools used and process integration, thereby shortening machining time and improving accuracy through single setup machining.

■Machines with U-axis mechanism

Service / Support

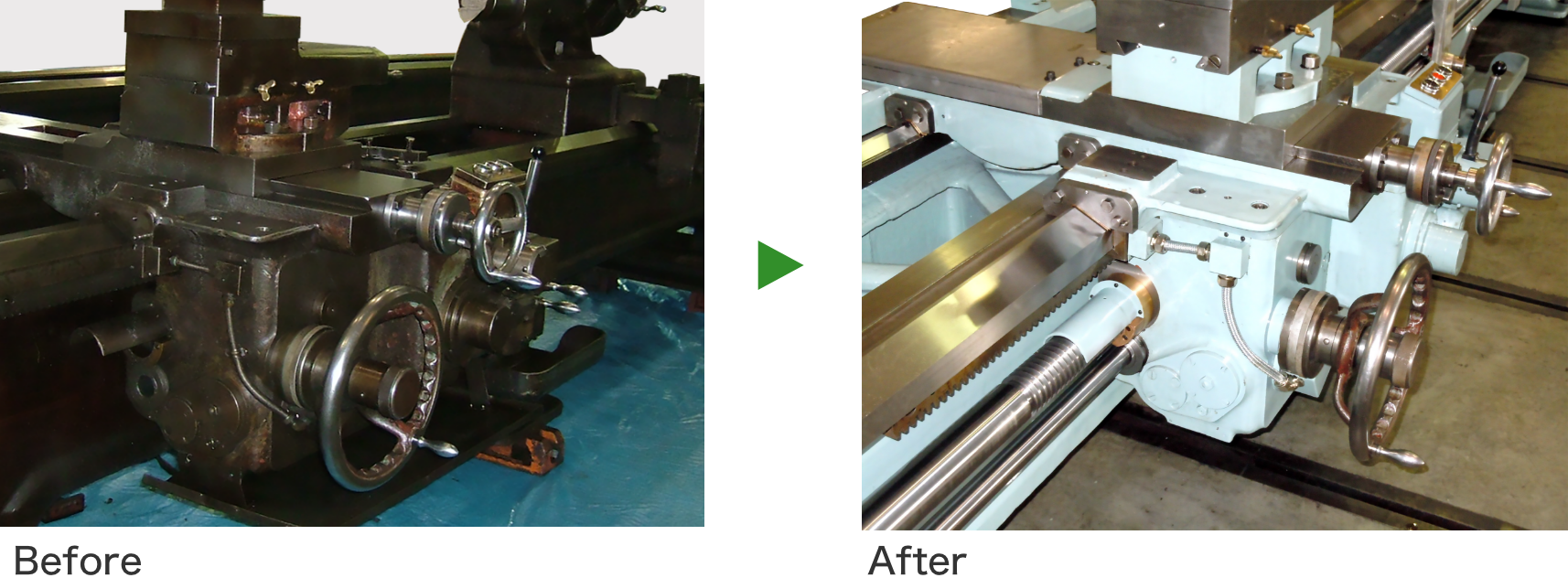

Overhaul

We will renew the machine by reassembling with polishing, hand scraping, etc. We accept not only Ikegai-made machines but also machines manufactured by others.

| Advantage 1 | You can use the same equipment you have been using for many years |

|---|---|

| Advantage 2 | Reusing equipment protects the environment |

| Advantage 3 | Investment costs can be reduced compared to purchasing new equipment |

Retrofit

We upgrade the performance of existing machines at your location by replacing to the latest NC equipment, main motors, servo motors, operation panels and adding various functions.

Inquiries

For inquiries regarding breakdowns, repairs, and various types of maintenance, please call, fax, or e-mail our nearest sales office.

Tokyo Office

3-43, Egasaki-cho, Tsurumi-ku, Yokohama

Kanagawa, 230-0002 Japan

TEL: +81-45-580-3651

FAX: +81-45-573-2851

Osaka Office

2-500-1, Takao, Miami-ku, Sakai

Osaka, 590-0157 Japan

TEL: +81-72-355-1810

FAX: +81-72-355-1812

United states

Sales / Service

SNK AMERICA INC. CHICAGO

1150 Feehanville Drive, Mount Prospect, Illinois 60056, U.S.A.

TEL: +1-847-364-0801

FAX: +1-847-364-4363

United states

Sales / Service

SNK AMERICA INC. LOS ANGELES

West Coast Branch 2791 Saturn St., Unit B Brea, California 92821, U.S.A.

TEL:+1-714-779-8818

Germany

Sales / Service

SNK GmbH

Daimlerstrasse 18, 73037, Goppingen-Ursenwang, Germany

TEL: +49-7161-99919-88

FAX: +49-7161-99919-79

China

Service

SNK NANJING TECHNOLOGY CORPORATION

Room101, Building 3, Zijin Entrepreneur R&D Center 89, Victory Road, Jiangning District, Nanjing, China

TEL: +86-25-5212-0211

FAX: +86-25-5212-0212

Korea Rep.

Sales / Service

SNK ENGINEERING KOREA CO.,LTD.

RM. 611 Pyeongchon Digital Empire, 16,Heungan-daero 427 Beon-gil, Dongan-gu, Anyang-si, Gyeonggi-do, KOREA Rep.

TEL: +82-31-8069-5121~2

FAX: +82-31-8069-5120

Taiwan

Sales / Service

SNK EG TAIWAN CORPORATION

2F-1, No.12, Sec.1, Pei-hsin Road., Hsin-tien Dist, New Taipei City, Taiwan

TEL: +886-2-2915-6765

FAX: +886-2-2915-6727

Thailand

Sales / Service

SNK THAI CO.,LTD.

Q District Gusto 299/264 Moo 14, Soi Kingkaew 37/5, Tambon Rachathewa, Amphur Bangplee, Samutprakarn, 10540, Thailand

TEL: +66-2-327-0601

FAX: +66-2-327-0605

India

Sales / Service

SNK INDIA PRIVATE LIMITED

1068, Vikas Nagar, Meerut road, Ghaziabad, Uttar Pradesh 201003, India